Project: ITER – Fusion For Energy

Location: South of France

Company: ITER

Cable type: Supply of key components of the ITER experiment

Tratos & ITER cooperation

Tratos & ITER cooperation

ENEA, a world leader in the design and production of superconducting cables for Controlled Thermonuclear Fusion, led by Eng. Anthony Court; Criotec Srl, experts in the manufacturing of components operating at very low temperatures and TRATOS, a leading global manufacturer of electric cables and optical fibre, together supply key components of the ITER experiment.

Built at Cadarache in France, its purpose is to demonstrate the scientific and technological feasibility of energy production by controlled thermonuclear fusion. Tratos and other members of the industrial partner community have been specifically identified and qualified by ENEA for joint participation in the contract, and a world-stage experiment.

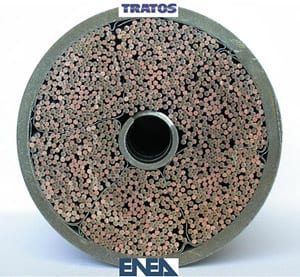

The tender was instigated by Fusion for Energy (F4E) for the production of Cable-In-Conduit (CIC) superconducting wire. The wire, manufactured by Tratos, was to be used in the worldwide construction of magnets for the ITER reactor and also the Japanese JT60SA. F4E awarded Tratos the contract for cabling and jacketing of approximately 20 km of ITER Toroidal Field (TF) conductors and in the region of 28 km of JT-60SA TF conductors, plus the jacketing of around 22 km of Poloidal Field (PF) conductors.

The superconductivity laboratory (ENEA) made its selection from the international firms chosen to tender, based on the synergy between the scientific and technical knowledge of ENEA and potential partners’ production capacity. Tratos and its partners had to create excellent prototypes to ensure the group succeeded against high-level international competitors.

The four-year contract, which is worth around €49 million, is managed by the ICAS consortium (Italian Consortium on Applied Superconductivity) and coordinated by ENEA. In addition to Tratos’ cabling and jacketing, ICAS is responsible for the procurement of the stainless tubes, wraps and central spiral required for the conductors. The copper and Niobium-tin (Nb 3Sn) superconducting wires (strands) for the ITER TF coils are supplied by F4E.

The cables for the ITER PF coils are supplied by the Russian Federation for final jacketing, in the frame of a bilateral agreement with F4E. The European contribution to the manufacture of the PF1 and PF6 coil conductors is approximately one-third, with the Russian ITER Domestic Agency procuring the remaining part. The schedule, technical aspects and legal issues for successful implementation of the contract were discussed during the kick-off meeting held between F4E and ICAS in early January 2011. Next ICAS went on to complete building the jacketing line; a stand of 800 metres where the jacket assembly, and inserting cable into the jacket, takes place.

The basic superconducting material supplied by Fusion for Energy and valued at around €90 million, went on to undergo initial processing by TRATOS at its Pieve Santo Stefano (AR) manufacturing plant, with the final assembly carried out by Criotec in Chivasso (Turin). ENEA’s task was to oversee and coordinate all activities to ensure the ‘the art’ of producing these components was realised.

Did you know?

Fusion is the energy that powers the stars. Our Sun is a gigantic fusion device, the biggest in our solar system. On earth, fusion research is aimed at demonstrating that this energy source can be used to produce electricity in a safe and environmentally benign way, with abundant fuel resources, to meet the needs of a growing world population.

Fusion for Energy (F4E) is the European Union organisation managing Europe’s contribution to ITER— the biggest scientific experiment on the path to fusion energy. This partnership of seven parties (China, Europe, Japan, India, the Republic of Korea, the Russian Federation and the USA), represents half of the world’s population and 80% of the global GDP. Europe is responsible for nearly half of the project, while the other six parties contribute equally to the rest.

Our mission is to bring fusion, the energy of the Sun and the stars, to Earth. To do so, we are working closely with industry and research organisations to provide the infrastructure and the components of the biggest fusion device. In parallel, F4E is involved in three major fusion R&D projects, stemming from the Broader Approach Agreement signed between Europe and Japan. Ultimately, F4E will contribute to the development of demonstration fusion reactors by offering technical know-how and expertise.

F4E was established on 19 April 2007 for a period of 35 years. Its headquarters are in Barcelona (Spain) and has offices in Cadarache (France) and Garching (Germany).

F4E possesses highly-qualified project managers trained as engineers, physicists, or administrators, working at the frontiers of science and technology.

F4E strives to be a world-class organisation in the way we manage our projects and report to our stakeholders by being accountable.

F4E has successfully build a partnership between industry and research by promoting innovative ways of collaboration to bring fusion energy closer.

Participating in this project, Tratos was very pleased to contribute toward achieving Goal 7 of the UN Global Goals to ensure access to affordable, reliable, sustainable and modern energy for all, Goal 9: Industry, Innovation and Infrastructure, Goal 13: Climate Action, GOAL 3: Good Health and Well-being,, and Goal 11: Sustainable Cities and Communities.