Offshore wind energy is finally coming of age. Now it is at the point where it can make a real and valuable contribution to power generation – and look to compete with traditional energy sources.

The problem it has is that too much of the hard-won clean electricity it generates is lost in transmission, through the cables carrying the power.

Energy expert Iñigo Azpiri, who is part of a team of European researchers studying the interconnection of offshore wind farms to land using HVDC grids to avoid power losses, says: “If industry manages to lower cable technology costs, we will be able to deploy a grid that can send renewable energy much further across Europe.”

And of course a contributor to costs is the level of power losses – and, says global cable innovator Tratos – the technology to stem those losses already exists.

WindEurope has underlined the importance of offshore wind farms in renewable power generation. According to WindEurope, Europe now has a total installed offshore wind capacity of 15,780 MW.

It says this corresponds to 4,149 grid-connected wind turbines across 11 countries. And it’s working well. Last year (2017) was a record year for wind-produced energy: generating twice as much as 2016.

However, most of the existing offshore wind farms transmit their power to the mainland using high-voltage alternating current and there are problems. Too much energy is lost in cables because of the distance cables have to travel. By their very nature wind turbines are located far from the mainland. This obstacle could be overcome using HVDC (high-voltage direct current transmission) that has much lower losses.

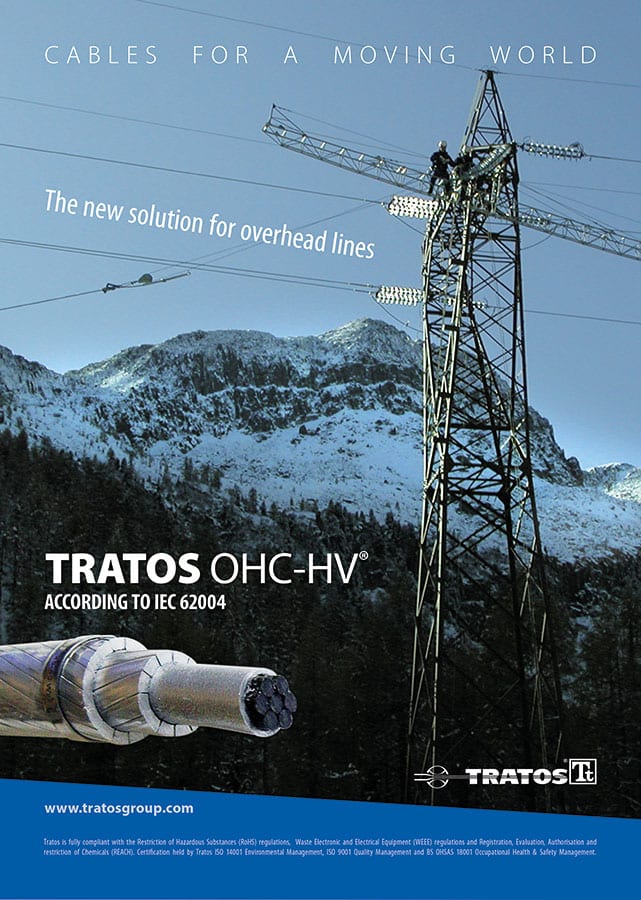

Tratos has developed, tested and successfully installed a completely new hybrid design of conductor for use in overhead lines based upon a high load carrying carbon fibre core with two compact, space saving, segmental thermal resistant aluminium alloy (AT1) wire layers, helically applied around in accordance with IEC 62004. This avoids the use of traditional conductor designs, based on existing technology, where any increase in transmitted power results directly in either an increase in size and hence the weight of the conductor, or an increase in the operating temperature above the recommended maximum operating temperature.

Iñigo Azpiri, Innovation manager at Iberdrola Renewables based in Bilbao, Spain, one of the world’s largest renewable energy firms has been vocal about the challenges of long distance power transmission.

He has been reported as saying that much more can still be done to prevent losses and, further, much more has to be done with the largest wind farm projects yet to come.

The biggest and most productive wind farms are sited at offshore distances of more than 120 km, where the wind blows with more constant speed and with less turbulence. So the gains to be had from this kind of consistency are worth it – but only if much more of the energy can be conserved and transported cleverly.

Tratos tested its new-generation hybrid solution cable in one of the most challenging land-based environments.

TERNA, a large Italian operator in electricity transmission grids, invited Tratos to install a high load carrying, low sag conductor in the San Pellegrino Pass in the Alps, on the 132 KV Moena-Cencenighe overhead line. The installation process proved to be comparable with those of a traditional conductor of a similar size.

A report prepared by the OEM after of the installation said: “The installation of the line at high altitude (2,000 meters above sea level) is a severe test for the conductor: in fact, at low temperatures the mechanical load is transferred from the carbon core to aluminium alloy coats, determining a state of high stress for the latter.”

Very low ambient temperatures are detrimental to overhead lines because cable reduces in length increasing mechanical tension applied to the pylons (in really severe cases pylons can be damaged or even collapse). Expansion and contraction in the aluminium tension applied to this relatively fragile material (instead of high strength carbon), can lead to excessive permanent elongation or even wire breakage and, at low temperatures, ice can grow on the conductor, causing a considerable weight gain, dramatically raising tension within the conductor.

The solution was to increase the current carrying capacity – with a newly developed, non-traditional conductor whose mass is not very different from a traditional ACSR (Aluminium Conductor Steel Reinforced) type.

Innovative new materials were used, in particular, an alloy with high conductivity, a maximum tensile strength comparable to pure aluminium and, more importantly, a maximum strength that remains unchanged at high temperatures. With this new alloy it is possible to build a replacement conductor with high thermal limits, working at temperatures not attainable with traditional counterparts.

New heat resistant materials combined with detailed attention to overall design resulted in the greatest increase in the conductors’ current carrying capacity. These new conductors simply replace existing conventional steel reinforced counterparts in transmission lines using existing pylons and towers, with the added benefit of a reduction in sag.

The conductor operated successfully without problems for several years before it was carefully removed, examined and re-evaluated by TERNA. The results of this work showed no deterioration in the Tratos OHC-HV.

In a recent editorial, Iñigo Azpiri went on to explore further the challenges of new-breed latest-technology wind turbines – and collecting and transporting the power they generate.

He added that the development of the technology has been spectacular. This is clearly illustrated by the fact that in the UK the cost of offshore wind energy has dropped by half in just two years, faster than predicted. This cost reduction has mainly been possible thanks to the latest wind turbine models, which, as I said, are much bigger than before. This increase of wind turbine power makes it possible to capture more wind while needing less foundation, less cable and fewer maintenance inspections.

He continued, saying that offshore wind energy will play an important role in the achievement of Europe’s 2020 renewable energy targets and will make it possible to power millions of homes with clean energy. But not only that, the development of new wind farms will employ thousands of people in the coming years.