Tratos Cavi has always had as one of its key objectives, the innovation of products in the various fields of its activities.

We have achieved this by means of the study and realisation of complex programs of research & development. One of the more important of these has led to the production of a Superconducting Cable HTS (high temperatures superconductivity) made up of “bisco “(Bi2223) tapes from “American Superconductors”.

In addition our company has been able to carry out meaningful developments on cables for overhead power lines with high thermal limits and reduced deformations at high loads; in the field of insulated, self-supporting, cables for medium and high voltage; that of composite special cables for transport of signalling and power in difficult conditions (earth moving equipment and mobile port equipment for moving loads)plus ,amongst many others,improved optical fibre cables for advanced use, including the military.

In this first part, we will illustrate the compact conductors of steel and aluminum, as substitution for copper cables, that have been developed for overhead use in collaboration with Enel and the Railways.

Compact conductors with steel support and high mechanical resistance, also with “Penetrante * Aluminium sheath”.

These have been carefully developed, in collaboration with Enel, in order to replace the crude copper conductors, frequently targeted by thieves, of overhead lines. This leads to remarkable advantages of weight, current capacity and ohmic resistance.We have also studied compact power cables for rail networks.

These are the fruit of the new technologies, developed and put into use by our company, they use the extrusion of aluminum sheaths onto cords of steel or other materials (as an example iron-nickel-molybdenum alloys or composites in spun carbon fibers and fibreglass).

*Aluminium fully extruded over the conductor to fill the outer layer interstices

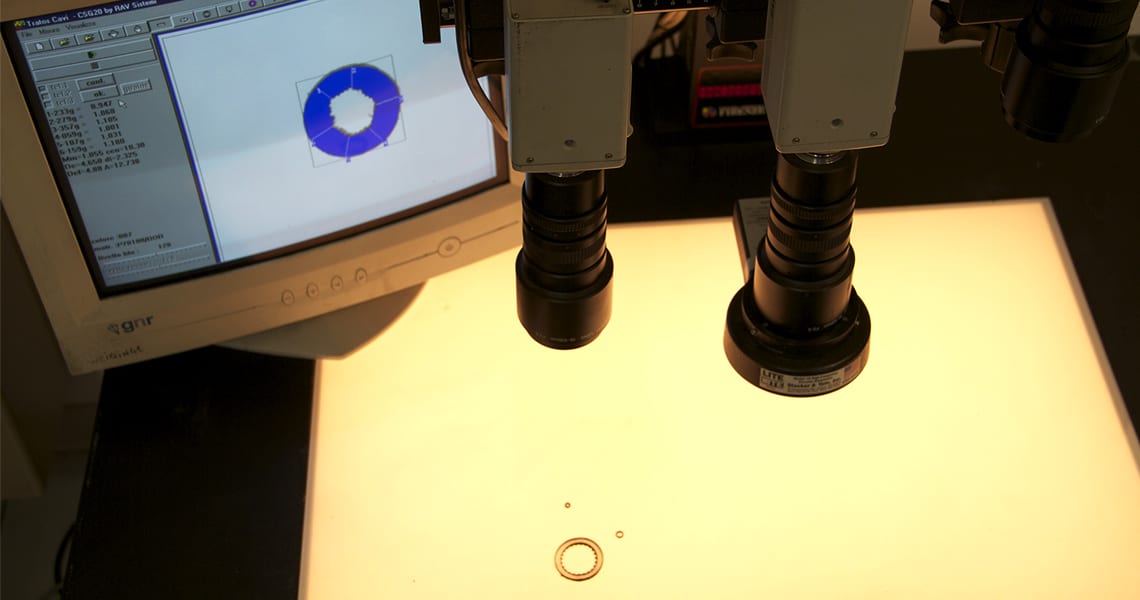

The cable types shown in the figure above have already become widely used by ENEL in Italy:Without these components, in order to dissipate vibrations caused by the wind, cables must be installed with appropriate dampers,these have been researched and developed by professor Diana of the Polytechnic of Milan after strict tests on live samples (Stockbridge type dampers characterisation).

The fastening vices and the joints have been researched and developed by the company “Gorla Morsetterie” in collaboration with our company: good result are obtained with “the preformato” type with threads in aluminum-magnesium alloy (Almelec) The substituition offers the advantages described below compared to plain copper:

| Compact cord Diameter 6.50mm Compared with plain copper conductors of 16mm2 | Compact cord Diameter 8.80mm Compared with plain copper conductors of 25 & 35mm2 | |

| Lower ohmic resistance (Ω/Km) | 0,947 compared to 1,118 | 0,507 compared to 0,720 & 0,519 |

| Lower unit weight (kg/m) | 0,111 compared to 0,141 | 0,205 compared to 0,228 & 0,317 |

| Lower coefficient of thermal expansion (1/°Cx10exp-6) | 13,5 compared to 17,0 | 13,5 compared to 17,0 & 17,0 |

| Higher tensile load (N) | 890 compared to 635 | 1425 compared to 1028 & 1425 |

| Lower cost of materials (€/Kg) | 1,46 compared to 2,90 | 1,46 compared to 2,90 & 2,90 |

| (€/m) | 0,164 compared to 0,410 | 0,299 compared to 0,662 & 0,918 |

| Larger current carrying capacity at 70°C | 100 compared to 90 | 215 compared to 140 & 190 |

With these compact conductors we have achieved the following objectives:

a) Optimisation of cross-sections

The result has been achieved, to significantly reduce the outer dimensions with respect to traditional cords for the same resistance and mass, or, vice versa, to significantly reduce the resistance for the same outer dimensions and mass.

b) Increase in operating temperature

These cords can be used , in suspension, even for temperatures over 90 °C as the tensile load is taken entirely by the steel and not the Aluminium which is prone to softening at higher temperatures.

c) (Low sag)

using, high-tensile steel molybdenum in place of ferronickel the cables can be suspended at greater mechanical tension with a resultant reduction in sag .

d) Increased performance

at

a working temperature of 150 °C, compact cords of 6,50 mm and 8,80 mm diameter, can carry 160 and 330 amperes respectiviely.

e) Reduced cost of materials

The use of aluminium in place of copper results in a dramatic reduction in costs for materials used, of the order of 70%.

Insulated conductors

These have been developed by our company, (always) in collaboration with Enel, for critical installations in difficult zones and have the advantage of reduced mass and dimensions with respect to traditional cables: moreover, the presence of the aluminum girdle prevents, more thoroughly, the longitudinal passage of water, avoiding complex fillers which were previously utilised. The insulation is made from a mixture of XLPE or plastics, in order to guarantee a working temperature of at least 90 °C

On insulated conductors of this type, various types of fastening and joints of span have been tested, taking to reference the standards BSI, N° plan 2006/00714 (draft EN 50397-2: 2007; covered conductors for overhead lines and related accessories): the preformate vices, with threads in aluminum-magnesium alloy (Almelec) have given the best results and have widely exceeded the tests previewed from the cited capitolato one.

Compact conductors for “binary” circuits at high current.

SHAPE * MERGEFORMAT SHAPE * MERGEFORMAT

These conductors have been researched for the Italian Railways in order to discourage the thefts of the usual copper types, the presence of the high-tensile steel inside the aluminum sheath acts, in fact, not to increase the breaking strength (which is already sufficient), but to ensure that the aluminum of the sheath and outer layers, if stolen need to be professionally recycled: in fact, the outer layers are made of an aluminium alloy (zirconium), that makes recovery of the aluminium a difficult and expensive proccess.

The cables in question can therefore achieve a permanent working temperature of 150 °C carrying a current of:

780 A if bare 725 A if insulated

The insulation is made from a special, scratch resistant, silicon rubber, that guarantee’s a working temperature of 150 °C and can also be used for emergency wiring.

Conclusions

The innovations, that we have described above, have led to a substantial contribution to the resolution of some complex technicial problems of overhead lines, but above all they have allowed a drastic cost reduction of the raw materials when compared to previously specified copper cables: additionally the ability to operste at higher temperatures (high thermal limit) acts to increase the transmitted power, negating the losses of a a higher resistance.

Plastic Insulation

14 concentric Al strands

10 concentric Al strands

Aluminium sheath Steel wire, φ 1.25mm

(Ing. G. Civili)