Following Tratos’ production of super-conducting cable for use in the International Thermonuclear Experimental Reactor’s (ITER) large electro-magnets, the company is pleased to report the winding has been completed and, for the first time ever, a Toroidal Field (TF) coil full-size super-conducting prototype of the double pancake (DP) is being manufactured.

An experimental fusion reactor, ITER will operate with a system of superconducting magnets which relies on the TF coils, the central solenoid, the Poloidal Field coils and the correction coils. The TF coils will be operated with an electrical current of 68 000 amps in order to produce the magnetic field which confines and holds the plasma in place in the ITER tokamak. Each TF coil weighs about 300t and is about 16.5m tall and 9.5m wide.

Each TF coil contains seven DPs which produce the magnetic field. Each DP is composed of a conductor length, which carries the electrical current, and of a stainless steel D-shaped plate called a radial plate, which holds and mechanically supports the conductor through grooves machined on both sides along a spiral trajectory. The conductor is composed of about 1000 superconducting and copper wires cabled inside a 2 mm-thick round stainless steel jacket 43.7 mm in diameter.

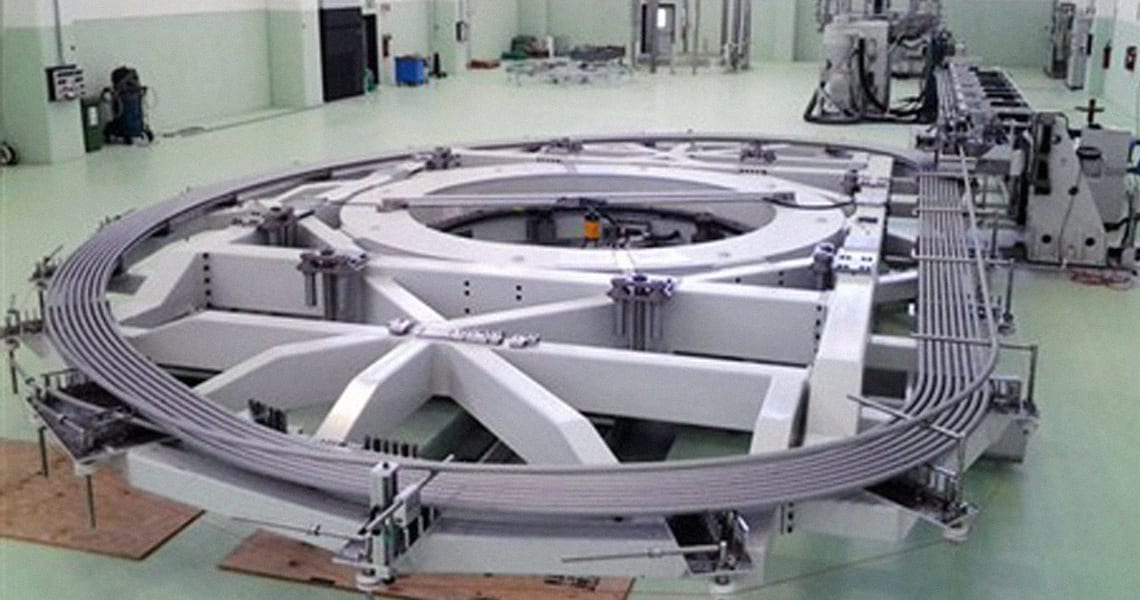

The cable was delivered on spool in a single 760m length, weighing seven tones. It was initially unspooled and straightened, after which the cable was cleaned and sandblasted, before being used and shaped into a 12m (l) x 9m (w) double pancake.

The winding of the DP, the most challenging component in the TF coil from the manufacturing point of view, consists of bending the conductor length along a D-shaped double spiral trajectory. Precision is essential – an accuracy as high as 0.01 % is required.

With the winding of the prototype now completed, other manufacturing steps are needed: the DP will be heat-treated at 650°C in a specially constructed inert atmosphere oven, then electrically insulated and finally transferred into the grooves of the stainless-steel radial plates. After assembly and the application of electrical insulation on the outside of the radial plate, the module is finally impregnated with special radiation-resistant epoxy resin, thus forming the prototype DP module.

Work has also begun on the Poloidal Field (PF) coils, with Fusion for Energy (F4E) awarding the engineering integrator contract which covers tooling, site and infrastructure, manufacturing and cold testing. The PF coil system consists of six horizontal, circular coils placed outside the toroidal magnet structure.