The second pillar of Tratos CO2 strategy is the reduction pillar. This pillar builds from the measuring pillar and goes a step further. Indeed, within this stage, Tratos, by recognising the environmental impact of its cables emerged from the measuring operations, attempts to reduce the carbon footprint emission of its cables.

There are different ways in which the company is trying to reduce the environmental impact of its products.

The first and more straightforward method is the planting of a certain number of trees that is equivalent to the CO2 emissions that each of the cables that the company produces has created throughout its entire life-cycle. Such emissions have been measured by the company in what has been defined as the measuring pillar.

Tratos aims to plant, by December 2020, a wooded area of at least 5,000 square meters in a place owned by Tratos itself. This operation leads to a CO2 absorption of approximately 4.6 tons CO2/year, considering that a wooded area would lead to a CO2 absorption of about 9.2 tons/ha per year (Data source for the calculation National Inventory of Forests and forest Carbon pools: INFC).

| CO2 absorption of the Tratos forest area |

| Method: Woodland area Site Toscany, Kenya Area (sqm) 5,000 Area (ha) 0.5 ton CO2 eq 4.6 |

The decision to plant new trees to compensate for the CO2 emission of the company’s products is not the only way in which Tratos attempts to reduce carbon emissions move towards a circular economy.

Indeed, as can be further discovered below, the company produces 95% of its own energy, only 5% of the energy the company uses is provided by the National Grid. Of this 95%, 10% comes from Tratos’ Water Plant, 30% from solar panels and 55% from the Tratos cogenerators.

The solutions that Tratos has adopted to increase its energy efficiency and reduce emissions are illustrated more in-depth below.

Energy Management Systems – ISO-50001

By complying with the ISO-5001 Tratos follows a systematic approach in achieving continual improvement of energy performance and the Energy Management Systems (EnMS).

Tratos Water Power Plant

Tratos has its own Water Plant that, with a power of 200kW, provides 10% of the total energy the company utilises. In addition to having used since 1980 its own water plant energy generation, Tratos is proud of the fact that in all its processes the water (thanks to a closed circuit) has always been reused inside the factory constantly,

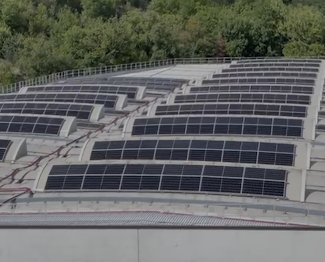

Tratos Solar Panels

Increasing its energy efficiency remains a top priority. Tratos has recently significantly improved its independent power generation capacity by installing solar panels. Currently, solar energy generation contributes to the supply of about 30% of total energy used by Tratos Group.

Terna – Tratos Cogenerator

Tratos is currently working with Terna on a project on a cogenerator. Tratos has installed in its factory in Italy a co-generator with a power of 1560 kW that transforms the water that the company has been using for its operation into energy.

MWM – Tratos Cogenerator

Tratos uses another cogenerator- MWM, which stands for highly-efficient and eco-friendly combined heat and power (CHP) plants for distributed power generation, and has over 150 years of experience in the development and optimization of gas engines for natural gas, biogas and other special gases.