Tratos’ packaging is manufactured from recycled material, including recycled wood for cable drums, and produced close to the company’s cable manufacturing site, reducing travel and emissions. The company is committed to reducing its impact on the environment and aims to keep its packaging carbon footprint as small as possible.

Installation and packaging recommendations for Tratos’ special cables.

STORAGE AND HANDLING

Drums’ storage and movement should be carried out by crane or forklift truck. Drums must not be dropped from truck to floor. Check for any damage sustained during transport before and during fitting to avoid problems once installed. Health and Safety procedures should always be followed.

Do not remove staves and cable end caps until immediately prior to installation. Cable end protectors should be replaced once the necessary length has been taken from the reel. Unwind and rewind cables as illustrated. When transferring cable between drums the cable’s minimum bending radius and the barrel drum diameters must be compatible.

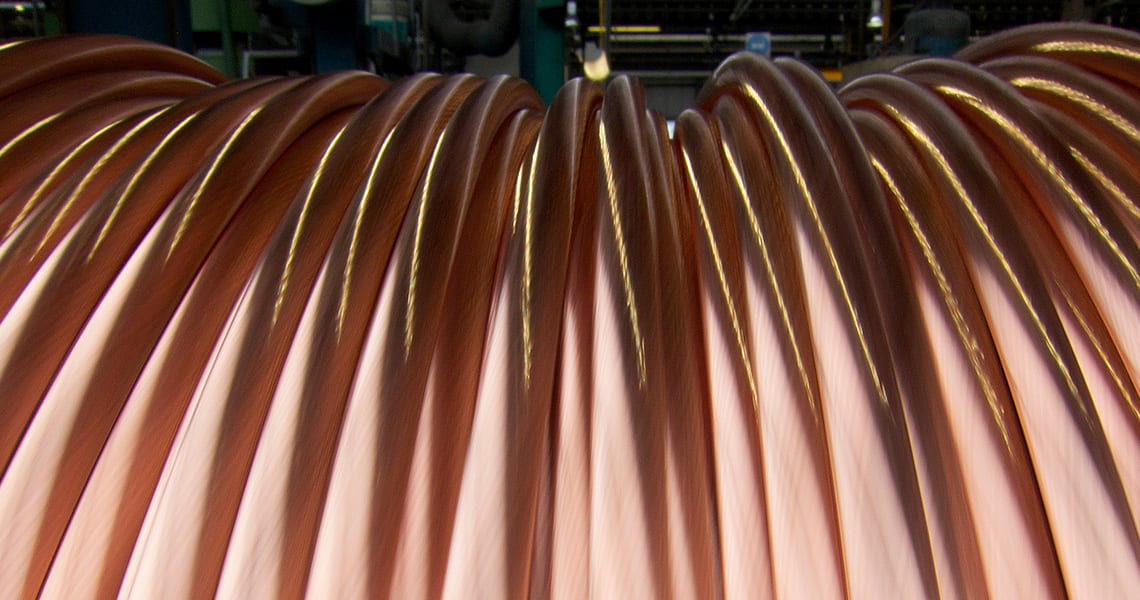

INSTALLATION RULES FOR MV CABLES

During installation of MV cables for fixed laying, and for ease of operation, it is advisable not to work with cable at temperatures below 5°C. Cable bending radii are indicated in the Range and Dimensions tables and it is important to note their values carefully. For unarmoured cables and to install cable inside pipes or trenches it is advisable to apply the following pull force on the conductors – being careful not to exceed 5 kg/mm2 of total area for copper cables and 3 kg/mm2 for aluminium cables.

Example:

copper cable 1 x 240 mm2: max pull force kg 1200

aluminium cable 1 x 240 mm2: max pull force kg 720

copper cable 3 x 240 mm2: max pull force kg 3600

aluminium cable 3 x 240 mm2: max pull force kg 2160

For steel cable armour the strain rope will be applied to the armour. Pull force by steel braid is advisable only for limited time periods.

If there are curves along the intended installation bed, sufficient conveyors must be used, for example at the entrance of pipes, to keep the cable in line and avoid exceeding the maximum pulling load.

For overhead cables, any strain will be on the supporting rope for installation operations and during working time.

The effects of thermal dissipation.

All installations in parallel trefoil must be realised with maximum care in order to achieve the most balanced charge distribution on the cables connected to the same phase. The following information should be considered:

- all cables must have the same metal conductors

- all cables must have the same length and section

- bundle cables must be made-up following R, S and T phases system

- cables must be properly spaced

- right and balanced connections should be made to the cables terminals.

DRUMS CAPACITY (metres)

HOW TO SELECT THE DRUM

Example:

1 – Type of cable: ARE4H1R-12/20 kV 1×240 mm2 overall cable diameter mm 39.1 a round figure mm 40 minimum bending radius mm 560 cable quantity mt 500

2 – determination of drum barrel diameter: = mm 560 x 2 = 1120 mm consequently qualified drums are BL180/ 200/ 220/ 250.

3 – outcome = following above practice the more convenient drum able to contain mt 500 is BL 18

DRUM DIMENSIONS

Note

This data refers to standard wooden drums used at all Tratos Cavi facilities. For special cable lengths Tratos can provide larger wooden and metallic drums. Transport restrictions may apply (e.g. special low-loading trailers and permits from traffic authorities in accordance with local regulations).

Disclaimer

TRATOS reserves the right at any time, without prior notice, to make variations on products described here. TRATOS is not responsible for improper use of its electrical cables.