Tratos Superconductor Cable for Fusion for Energy Application

Tratos has been part of the International Thermonuclear Experimental Reactor’s (ITER) Fusion4Energy project for more than a decade.

Tratos has been involved in the ITER (International Thermonuclear Experimental Reactor) fusion for energy cable project since its inception.

The company purpose-built cable creates some of the biggest and most challenging superconducting electromagnets ever produced in the history of mankind.

Tratos is responsible for the production of Cable-In-Conduit (CIC) superconducting wire. The wire was destined for the worldwide construction of magnets for the ITER reactor and also the Japanese JT60SA. F4E (Fusion4Energy) awarded Tratos the contract for cabling and jacketing of approximately 20 km of ITER Toroidal Field (TF) conductors and in the region of 28 km of JT-60SA TF conductors, plus the jacketing of around 22 km of Poloidal Field (PF) conductors.

ICAS (Innovation and Consulting on Applied Superconductivity) was founded in September 2010, with the original scope of supplying the European portion of the superconducting conductors for the ITER and the JT-60SA nuclear reactors, in France and Japan. It provides services and products serving Superconductivity and High Tech power applications.

Contact us:

Tel: +44 20 3148 5178

e-mail: [email protected]

Please don’t hesitate to contact us if you need additional information about our products.

Application

Tratos is responsible for the production of Cable-In-Conduit (CIC) superconducting wire. The wire was destined for the worldwide construction of magnets for the ITER reactor and also the Japanese JT60SA. F4E (Fusion4Energy) awarded Tratos the contract for cabling and jacketing of approximately 20 km of ITER Toroidal Field (TF) conductors and in the region of 28 km of JT-60SA TF conductors, plus the jacketing of around 22 km of Poloidal Field (PF) conductors.Standards

Technical Specifications

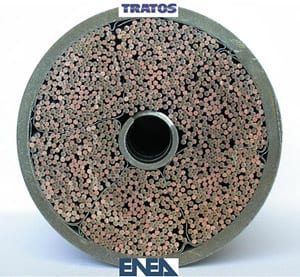

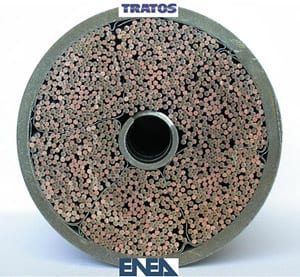

The conductor cable is composed of about 1000 superconducting and copper wires inside a 2 mm-thick round stainless steel jacket, 43.7 mm in diameter.

Tratos’ cable was delivered on-spool in a single 760m length, weighing seven tonnes. It was initially unspooled and straightened, after which the cable was cleaned and sandblasted, before being used and shaped into a 12m (l) x 9m (w) double pancake.

Contact us

Please, don’t hesitate to contact us for additional information on our company or our products.

Related Case Studies

Other News

-

Tratos Celebrates a Successful Showcase at Middle East Energy 2025

-

Tratos participates in the UKEF Supplier Fair on Cabinda International Airport

-

Strategic Growth in Fibre Optic Technology for Tratos

-

Tratos Cavi Wins BTOB Award for Innovation

-

Egidio Capaccini Award 2024 edition

-

Tratos Cavi acquires AFL Telecommunications GmbH's German Plant

-

Tratos Visits CEECATL-China

-

Tratos Group Leaders Participated in ROG.e 2024 in Brazil