27th International Conference on Electricity Distribution – Rome, 12-15 June 2023

Development of new cable solutions and evaluation of the reduction of carbon emissions

Thee three sustainable solutions above were included in the Global Tender for cable and conductor 2021 on a selection of material codes with a higher spending for Italy and Spain.

The implementation of these initiatives were achieved thanks to three suppliers: Nexans, Prysmian and Tratos.

The cable production lines have not changed since the production process of these new solutions is identical to that of traditional cables.

The only difference from the production of the standard cables is the implementation of sustainable raw materials.

The need to track cables produced from sustainable materials requires an organization of warehouses to ensure separate storage of these raw materials and an organization of the production line in such a way that it is only dedicated to this specific product for a certain period of time.

The cables were manufactured and tested successfully according to the Enel Global Specifications.

To evaluate the environmental impact associated with their production and to compare them with traditional solutions, it was required to the Suppliers to estimate the product carbon footprint of these new sustainable solutions and to compare it with that of the standard to determine the potential carbon footprint reduction.

This calculation were carried out according to ISO14067 (cradle to gate).

For this purpose, the entire production chain is taken into account, starting with the extraction and production of raw materials and ending with the production of the cable, also including the CO2 produced during the transportation.

Considering that the cable production process is the same, the difference in CO2 emissions is due to the different input of raw materials.

The part of the cable that contributes the largest carbon footprint is the conductor material. Acting on the conductor, using recycled material, could lead to a more considerable reduction in emissions.

Furthermore, it is worth noting that even in the area of plastics, there is a difference between the CO2 emissions of bioplastics and recycled plastics as they have two significantly different origins.

For PE of vegetable origin, the CO2 absorption at the start of plant life can be considered in two ways:

1) include as negative emissions at the beginning (absorption) and sum the positive contribution at the end-of-life the greenhouse gas emissions (cradle to grave);

2) consider both the CO2 absorption contribution at the beginning of life and the emission contribution at the end of life to be zero.[4-5]

As the present analysis is based on the cradle-to-gate cycle, the contribution represented the CO2 storage of the plants was taken into account.

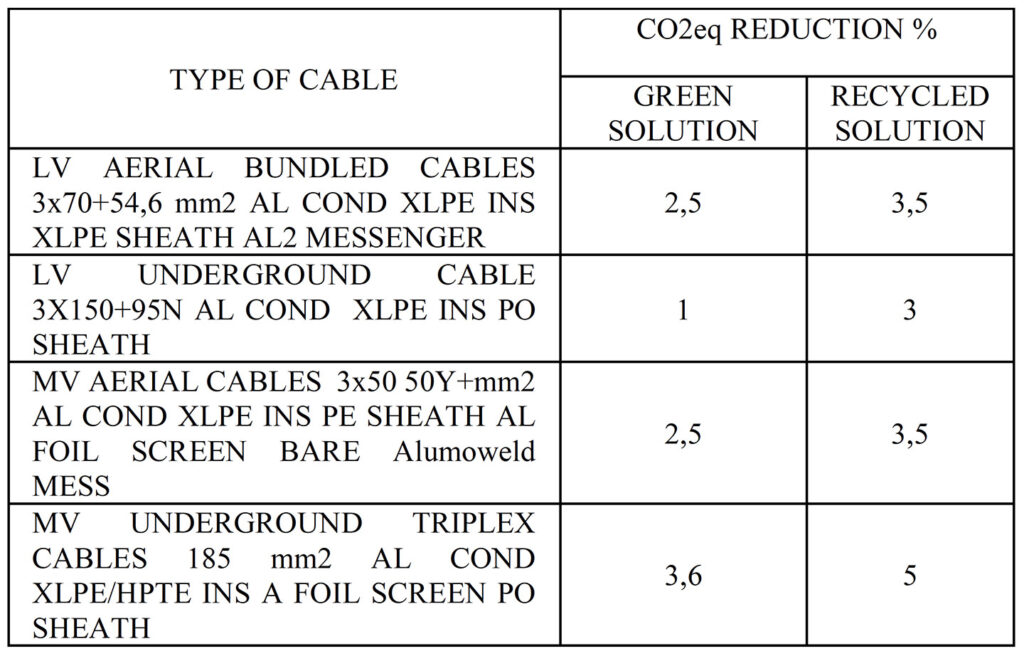

The following table shows the results obtained about percentage reduction in carbon footprint for four identified samples (two low-voltage and two medium-voltage examples were selected from the lot of cables). As can be seen from the table, the calculations have proved that the use of plant-based materials and the use of recycled materials leads to a reduction in CO2 emissions of up to 5%.

A greater reduction is achieved by using recycled material than by using polyolefin of vegetable origin.

Clearly, greater reductions occur in the case of cables with higher tension levels and larger cross-sections (larger amounts of material involved).