In recent years, Tratos Cavi has undertaken an intense activity of Industrial Research and Experimental Development aimed at product innovation, in some cases radical (new product), in others incremental (product improvement). The aim is to identify solutions with specific performance characteristics in order to fully respond to the needs of their target context.

FiberCable4.0

The research project involves the design, development and production of highly innovative fibre optic cables for fixed installation with thermoplastic sheath, with data transmission potential 33% higher than state of the art, in order to allow the adoption of 5G and even 6G connection technologies in the country, thus contributing to strengthening the infrastructural communication network which enables the Industry 4.0 paradigms (a project financed by the Tuscany Region as part of the Regional Operational Program ERDF 2014-2020 Call for bids no.1: Strategic Research and Development Projects);

Capacity

Development of innovative materials based on polymeric compounds including nanofillers and/or bio-based polymers, and their use for manufacturing cables for energy transport, data transport and telecommunications, characterised by improved performance and greater sustainability of the entire life cycle, thanks also to process innovations and to the design for recovery and recycling of materials (a project financed by the Tuscany Region as part of the Regional Operational Program FESR 2014-2020 Call for bids no.1: Strategic Research and Development Projects);

- Development of new Icephobic cables;

- Development of new AB-OPGW detachable safety lines with optical fibres;

- Development of new flame retardant formulations with better performance than those required by the CPR legislation and such as not to require changes in the production processes.

TRATOS HV has conducted an intense activity of Industrial Research and Experimental Development as part of a multi-year project of high strategic value for the company. The project in question, which began in 2016 and whose end (following an extension) took place in 2019, is among the projects financed by the Ministry for Business and Made in Italy within the aid project “Fondo Crescita Sostenibile – Bando Horizon 2020”.

Presented by Tratos HV and the Department of Chemistry, Biology and Biotechnology of the University of Perugia, it proposes a product innovation through the study and development of a new family of medium and low-voltage cables for mobile laying applications (with particular emphasis on the supply of operating machines). The key aim of the project is to replace the current coating sheath, currently made of polychloroprene with the addition of equally critical substances in terms of environmental impact and safety in the workplace, with innovative nanostructured non-toxic compounds. The use of nanostructured materials must give the new compound excellent flame retardant, gas barrier properties and good mechanical properties, as required by the scope for which it is intended.

To achieve this objective, we have envisaged the adoption (as nanostructured materials) of inorganic-organic additives belonging to the chemical classes of lamellar solids such as functionalised hydrotalcites, functionalised montmorillonites and functionalised zirconium phosphates and phosphonates.

The new compound must give the cable the same characteristics ensured today by the polychloroprene sheath with the advantage of overcoming the limits and critical issues deriving from the use of traditional cable, in particular:

- the emission of toxic and corrosive fumes during combustion, in case of fire;

- the use of specialised personnel for production, as it is difficult to process, in addition to

- the high production of waste both during compounding and during retrusion.

The aim of the project is, therefore, to identify one or more completely innovative compounds which, used as a base for the new cable coating, allow achieving several results (both technical and qualitative) and that demonstrate the technological leap of the proposal. These include:

- compliance with the CPR – CEI 50399 standard, with specific reference to obtaining a fire retardant compound;

- reduction of the specific weight of the cable by about 15%;

- obtaining a production process in which the use of cross-linking agents such as ETU and antioxidants such as Premix MBTS and TMQ is no longer required;

- in case of fire, the development of non-toxic combustion fumes, according to the CEI EN 50267 standard.

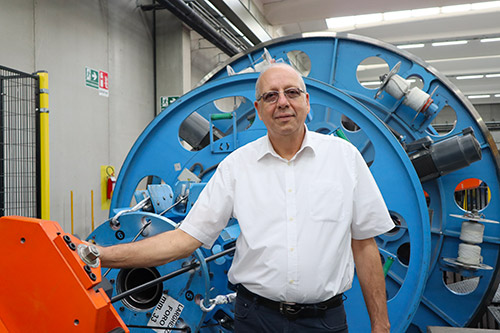

TRATOS-ENEA:100 km of superconducting cables made in Italy for international fusion projects

Committed to developing new energy solutions

Energy demand will undergo a steep increase in the following decades while the fossil fuel reservoirs will presumably dwindle at least as fast.

Tratos contributes to a process that can guarantee conspicuous, non-intermittent and reliable energy production and research on low-carbon foot cables.

Nuclear fusion is a very promising alternative that satisfies the requirement of having a reliable energy source and is very likely to play a pivotal role in the energy arena.

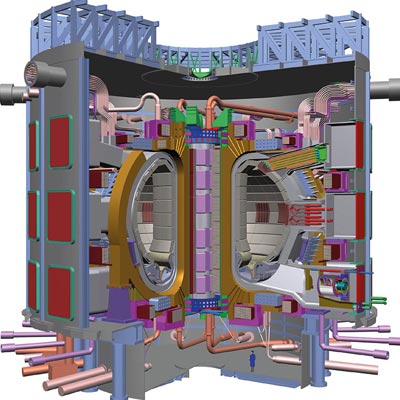

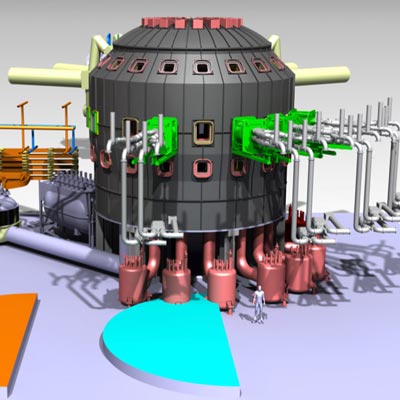

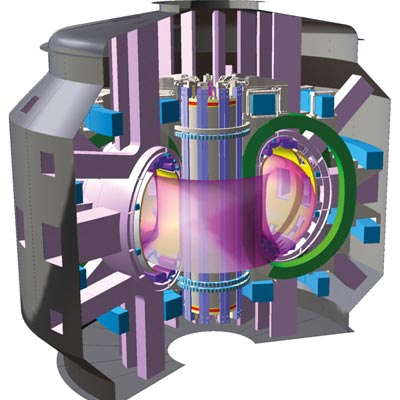

To date, the most advanced way to harness fusion energy is represented by tokamak machines, where nuclear reactions take place within a torus-shaped plasma that must be confined in the reaction chamber by means of the intense magnetic field.

Many of the superconductive cables for the Cadarache fusion plant were produced in Tratos Cavi.