Antonio della Corte

The ENEA Superconductivity section plays a very important role in all the experimental campaigns for the characterization of ITER conductors and magnets and for various superconducting/cryogenic components of LHC of CERN, as well as the monitoring of the manufacturing of conductors and magnets carried out by LUVATA (ex Europa Metalli, EM) and ANSALDO Superconductors (AS), which are the two industries in Italy mostly involved for what concerns the production of strands, cables and magnets.

Under our direct supervision, in 1978, EM began the construction of a conductor in NbTi for the first large scale superconducting coil completely designed and realized in Italy by AS. This coil, with a max field of 6T and an inner diameter of 1.3m, was completed in 1980 and installed in the SULTAN experimental facility (Villigen, Switzerland), where it is still operative.

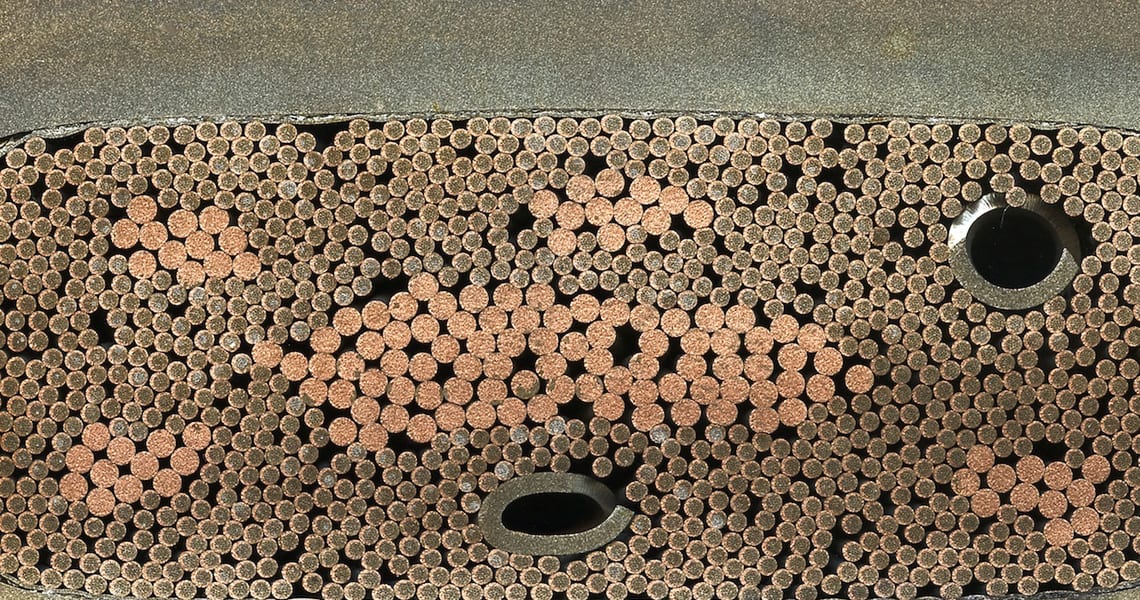

A section of the CICC conductor for the ITER

magnet. The external steel jacket is about

50 mm x 50 mm Prototype of ITER

TFMC (Toroidal Field

Model Coil).

The experience gained allowed our group together with EM and AS to to realise the CICC (Cable-in-Conduit Conductor) type conductor for a 12T Nb3Sn magnet and, later on, the full-size conductor for the Toroidal Field Model Coil (TFMC) of ITER, successfully tested at FzK (Karlsruhe,Germany) in 2002.

In 2003 collaboration with EM and AS was dedicated to to manufacture the full-size conductor for the winding of the PFCI (Poloidal Field Coil Insert) relevant for ITER. The conductor was tested in spring 2004 at SULTAN, while a model coil, wound with the same conductor, will be tested in spring 2007 at Naka (Japan).

In 2003 collaboration with EM and AS was dedicated to to manufacture the full-size conductor for the winding of the PFCI (Poloidal Field Coil Insert) relevant for ITER. The conductor was tested in spring 2004 at SULTAN, while a model coil, wound with the same conductor, will be tested in spring 2007 at Naka (Japan).

As the final phase of ITER construction of is coming closer and closer, the conductor production for its realisation will increase in a significant way and thus also the engagement for the test in operative conditions. The only European facility which can carry out such measurements is SULTAN, which however cannot handle the huge quantity of work requested. Therefore, the European Community has decided to realise a new facility which will use a dipole magnet wound by CIC conductors with the “Wind&React” technology: the European Dipole.

Our group is actually assigned with the monitoring of the conductor manufacture, based on Nb3Sn Advanced Strand (see Nb3Sn material), produced by Luvata.

In this field, we have developed and patented a new type of joint for CIC-type superconductor cables which will be used to assemble the different lengths of conductor for the dipole winding.

Under our monitoring, Luvata has realised the first full-size prototype conductor for ITER’s toroidal coils based on Nb3Sn Advanced Strand, which is going to be tested in SULTAN. ENEA is also responsible for the design, test and realisation of the 18 NbTi toroidal superconducting coils for a new Tokamak, the JT60-SA(Naka, Japan) experimental reactor, whose construction is part of the ITER project. This work is carried out in collaboration with the CEA (France) and JAEA (Japan).

e-mail: dellacorte@frascati.enea.it

tel.: +39 06 9400 5720