An Anglo Italian cabling company at the forefront of superconductor development is among a group of world innovators investing heavily in game-changing technology that is set to mature in the next 20 years.

Tratos, which develops and manufactures high-performance cable in both countries, and has bases worldwide, was one of the first to recognise the importance of committing to a long-term focus on superconductivity.

Today, alongside fellow producers in China, Japan, Korea, Russia, the US and across Europe, Tratos is a pivotal driver of some of the industry’s most exciting technology.

In the years that development work has been underway, significant landmarks have already been reached with production lengths of toroidal field conductor coming off jacketing and compaction lines and poloidal field copper dummy jacketed for Russia.

Tratos’ team has been a fixture at the industry’s conductor ignition meetings. The events are designed to bring together members of the magnet teams from ITER* and the Domestic Agencies, ITER Organisation contractors, and industrial suppliers from the six producing ITER Domestic Agencies.

These stakeholder organisations play an important part in the review of the status of magnet qualification activities, strand production, cabling, and jacketing; Tratos is part of the ICAS consortium (ENEA, Tratos Cavi, Criotec).

The ENEA Superconductivity section plays a very important role in all the experimental campaigns for the characterisation of ITER conductors and magnets and for various superconducting/cryogenic components of LHC of CERN. It also monitors the manufacturing of conductors and magnets carried out by LUVATA (ex Europa Metalli, EM) and ANSALDO Superconductors (AS), which are the two industries in Italy most heavily involved with the production of strands, cables and magnets.

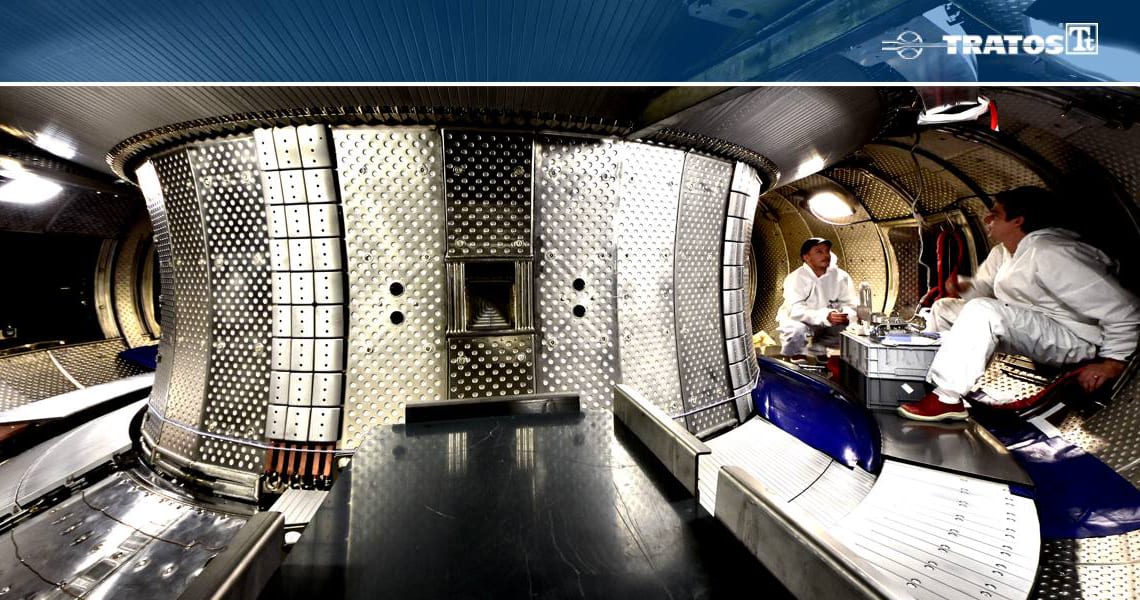

Already active in delivering today’s forerunner technology, Tratos has been working, as part of the consortium, on superconducting wire for the €49m world ITER reactor and the Japanese JT60SA. Tratos has produced the superconductor that makes Tokamak work; producing the cabling solution that delivered the required results.

The four year contract saw the company contracted to provide the superconducting Cable-In-Conduit used in the construction of magnets for these projects. Tratos has already supplied the first order, on a contract that runs through to 2017.

*ITER is an international project to design and build an experimental fusion reactor based on the “tokamak” concept. The project, which is currently under construction in the South of France, will demonstrate the feasibility of energy production by controlled thermonuclear fusion.

Notes to editors

The International Thermonuclear Experimental Reactor (ITER) project represents the next step in the development of fusion energy. ITER will be the first fusion plant to have almost the same dimensions as a conventional electric power station.

ITER’s mission is to demonstrate the scientific and technological feasibility of fusion as an energy source. The detailed design of the reactor has been thoroughly tested through intense R&D activities carried out by hundreds of researchers and technicians at numerous laboratories, universities and industries all over the world.

The European Union, Japan, Russian Federation, United States, the People’s Republic of China, the Republic of Korea and India officially signed the agreement to realise ITER at Moscow on 28th June 2005. Construction began in 2007 at the European site of Cadarache in the south of France.

Sidebar for superconductivity piece

(NB please note that the following information enables the story to have some current information included although Tratos’ input may not be so new)

Superconductivity Development Achieves Huge Gains through the summer

Late summer 2015 saw huge strides forward for the project Tratos is a major stakeholder in.

August saw the first Fusion for Energy (F4E) component for the Neutral Beam Test Facility (NBTF), the SPIDER High-Voltage Deck (HVD), delivered and accepted at the NBTF at the Consorzio RFX site in Padua, Italy.

The HVD is now ready to host the Ion Source and Extraction Power Supplies (ISEPS) which are necessary for feeding the ion source of the Neutral Beam injector.

The SPIDER Transmission Line (TL) is the component on which work will focus during the coming months with the manufacturing stage of the TL coming to an end by November this year and anticipated site installation before the end of 2015.

August also saw work on JT-60SA take a rapid step forward with the final acceptance tests of the quench protection circuit (QPC) for the successful completion of the superconducting coils.

In September an imposing steel structure rose to overlook the Tokamak complex. The Assembly Hall building is where the high-tech components of the biggest-ever fusion device will be put together.

The building is 100 metres long, 60 metres wide and 60 metres high. Its construction started seven months prior with a workforce of 50 on site to tackle challenges on a scale to match the building itself including building the roof on the ground from where it would be eventually lifted. A team of engineers worked round the clock, and, in the days and nights proceeding the lift they had to fix more than 65,000 bolts. Thanks to creative planning, the mammoth undertaking was completed three months earlier than planned.