TRATOS®Kynar/PVC Armoured

Cathodic Protection Cable

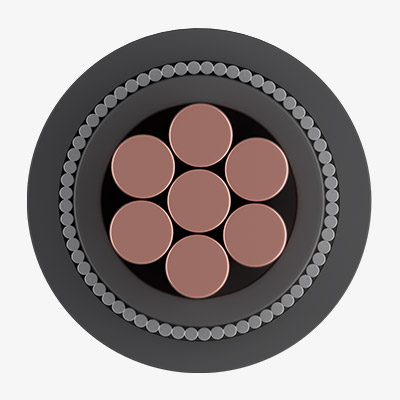

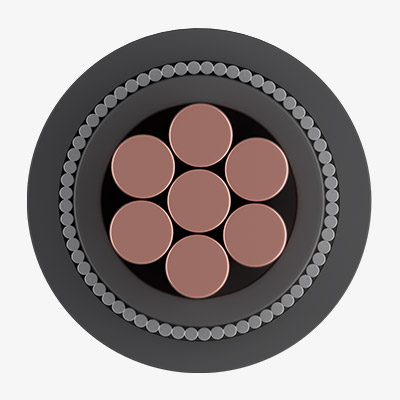

Kynar insulated, Polyvinylchloride (PVC) inner sheath, Galvanised steel wire armour, Polyvinylchloride (PVC) outer sheath, single core cable.

This single-core armoured cable is designed for use as the connecting cable in cathodic protection systems worldwide, the armour lends itself to direct burial installations, although, for continuous immersion in water, an HDPE sheath gives greater protection. A fluoropolymer, Polyvinylidene fluoride (PVDF), Trade name Kynar, is a tough engineering thermoplastic, well known for its excellent resistance to a wide range of chemicals, most acids and acid mixtures, weak bases, halogens, halogenated solvents, hydrocarbons, alcohols, salts and oxidants. Kynar has high dielectric strength and excellent mechanical properties over a wide temperature range leading to it becoming a popular choice as a reduced wall primary insulation. Kynar has low permeability leading to its choice for special applications such as cathodic protection where chlorine and hydrogen gasses could be present.

Immediately over the inner layer of Kynar Tratos extrude an inner layer of High-Density Polyethylene (HDPE) Molecular Weight Polyethylene and then apply a helical layer of Galvanised Steel wires. The outer sheath is a thick layer of High-Density Polyethylene (HDPE) which is a member of the thermoplastic polyethylene (PE) family. The higher the density of the material, the greater the crystallinity and, therefore, the greater the hardness and stiffness. Primarily HDPE is used as a sheath because of its toughness and excellent water resistance, though it also has good resistance to chemicals and some solvents. However, it has only moderate resistance to oils and, although classed as halogen-free, has the disadvantage of being flammable. Low-temperature performance is very good. Unlike PVC sheathed cables which should not be installed or flexed when the temperature is below 0oC polyethylene sheathed cables can be safely installed at sub-zero temperatures.

Tratos XLPE/HDPE cables offer performance and reliability over an extended lifetime in cathodic protection applications where moisture or water are present continually or for long periods of time. HDPE coverings also provide corrosion protection in installations where this is a problem.

Contact us:

Tel: +44 20 3148 5178

e-mail: [email protected]

Please don’t hesitate to contact us if you need additional information about our products.

Application

Tratos Cathodic Protection Cables are single conductor cables that are intended to carry a DC current to anodes and cathodes in a cathodic protection system. Tratos Cathodic Protection Cables are designed for use in both active and passive cathodic protection systems to eliminate and prevent corrosion in Metals. Tratos Armoured Cathodic Protection Cables are intended for installation in arduous operating conditions where the risk of mechanical damage is higher than normal. Tratos Cathodic Protection Cables are used to eliminate and prevention the corrosion of steel pipelines and steel storage tanks, offshore oil and gas installations, offshore wind farms, ships and other maritime applications installed in air or water.Specifications

- Conductors: Plain annealed copper conductors – BS EN 60228 Class 2

- Insulation: Kynar- Polyvinylidene fluoride (PVDF)

- Inner Sheath: High Density Polyethylene (HDPE)

- Armour: Galvanised steel wire

- Outer Sheath: High Density Polyethylene (HDPE)

- Standard size range: 10mm2 to 50mm2 (up to 185mm2 available on request)

- Standard insulation colours are RED and BLACK

Standards

Technical Specifications

- Minimum ambient air temperature -55 oC

- Maximum continuous conductor temperature +105 oC

Minimum bending radius – Fixed Installation – 8D

Maximum allowable pulling tension:

- 50N/mm2 during installation

- 15N/mm2 in service

Additional Information

CONDUCTOR – Material: Compacted tinned annealed Cu

| Nominal CSA | Nominal Diameter | Max. resistance 20oC |

| mm2 | mm | Ω/km |

| 10 | 3.8 | 1.84 |

| 16 | 4.65 | 1.16 |

| 25 | 5.83 | 0.734 |

| 35 | 6.8 | 0.529 |

| 50 | 8 | 0.391 |

| Nominal CSA | Nominal Diameter | Max. resistance 20oC |

| mm2 | mm | Ω/km |

| 10 | 3.8 | 1.84 |

| 25 | 5.83 | 0.734 |

| 35 | 6.8 | 0.529 |

| 50 | 8 | 0.391 |

INSULATION – Material: XLPE

| Nominal thickness | Nominal Diameter |

| mm | mm |

| 0.5 | 4.80 |

| 0.5 | 5.65 |

| 0.5 | 6.83 |

| 0.5 | 7.8 |

| 0.5 | 9.0 |

| Nominal thickness | Nominal Diameter |

| mm | mm |

| 0.5 | 4.80 |

| 0.5 | 5.65 |

| 0.5 | 6.83 |

| 0.5 | 7.8 |

| 0.5 | 9.0 |

INNER SHEATH – Material: HDPE

| Nominal thickness | Nominal Diameter |

| mm | mm |

| 0.8 | 8.0 |

| 0.8 | 8.85 |

| 0.8 | 10.4 |

| 0.8 | 11.4 |

| 0.8 | 12.8 |

| Nominal thickness | Nominal Diameter |

| mm | mm |

| 0.8 | 8.0 |

| 0.8 | 8.85 |

| 0.8 | 10.4 |

| 0.8 | 11.4 |

| 0.8 | 12.8 |

ARMOUR – Material: Galvanised steel wires

| Nominal Diameter |

| mm |

| 0.9 |

| 0.9 |

| 0.9 |

| 0.9 |

| 0.9 |

| Nominal Diameter |

| mm |

| 0.9 |

| 0.9 |

| 0.9 |

| 0.9 |

| 0.9 |

OUTER SHEATH – Material: HDPE

| Nominal thickness | Nominal Diameter | Nominal weight |

| mm | mm | kg/km |

| 1.5 | 11.2 | 140 |

| 1.5 | 12.05 | 200 |

| 1.5 | 13.23 | 290 |

| 1.5 | 14.2 | 395 |

| 1.5 | 15.4 | 505 |

| Nominal thickness | Nominal Diameter | Nominal weight |

| mm | mm | kg/km |

| 1.5 | 11.2 | 140 |

| 1.5 | 12.05 | 200 |

| 1.5 | 13.23 | 290 |

| 1.5 | 14.2 | 395 |

| 1.5 | 15.4 | 505 |

Contact us

Please, don’t hesitate to contact us for additional information on our company or our products.

Other News

-

Tratos Celebrates a Successful Showcase at Middle East Energy 2025

-

Tratos participates in the UKEF Supplier Fair on Cabinda International Airport

-

Strategic Growth in Fibre Optic Technology for Tratos

-

Tratos Cavi Wins BTOB Award for Innovation

-

Egidio Capaccini Award 2024 edition

-

Tratos Cavi acquires AFL Telecommunications GmbH's German Plant

-

Tratos Visits CEECATL-China

-

Tratos Group Leaders Participated in ROG.e 2024 in Brazil